What Is Sustainable Logistics? Key Benefits & Examples

In Belgium, Nike has reimagined its European Logistics Campus through sustainable innovation. This facility now operates entirely on renewable energy, harnessing power from solar panels and wind turbines. Its unique construction utilises storage racks as a self-supporting system, significantly reducing material usage and waste. Moreover, by shifting a substantial portion of its freight transport to waterways, Nike has eliminated the need for approximately 14,000 truck journeys annually, cutting carbon dioxide emissions by 30%.

This transformation reflects a broader shift in logistics—from traditional, carbon-intensive methods to sustainable, efficient practices. As global supply chains grapple with environmental challenges, the logistics sector stands at a crossroads. Embracing sustainable logistics is no longer optional; it’s imperative for businesses aiming to thrive in a rapidly evolving system.

In This Article

- What Is Sustainable Logistics?

- The Environmental Toll of Traditional Logistics

- Key Benefits of Sustainable Logistics

- Real-World Case Studies

- Key Components of Sustainable Logistics

- Challenges and How to Overcome Them

- Actionable Advice for Businesses

- Conclusion: Looking Ahead – The Future of Logistics Is Green

What Is Sustainable Logistics?

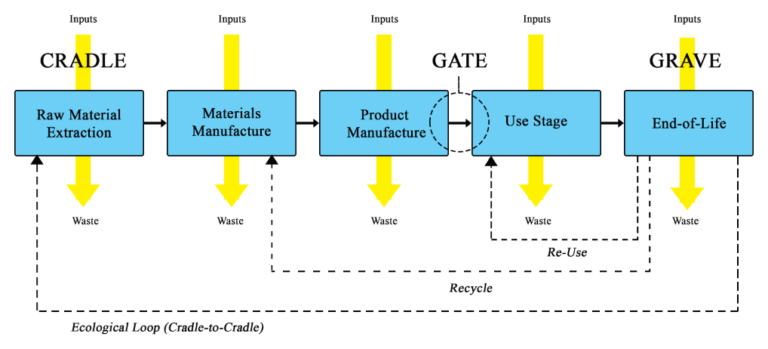

Sustainable logistics is about moving goods in ways that are kinder to the planet, smarter for business, and better for people. It’s not just about swapping diesel trucks for electric ones—it’s about rethinking how we package, ship, store, and return products to reduce waste and emissions at every step. The goal is to minimise environmental impact while maintaining efficiency and profitability. This includes optimising delivery routes, using renewable energy in warehouses, adopting recyclable packaging, and embracing circular systems that reuse materials instead of discarding them.

The Environmental Toll of Traditional Logistics

The logistics industry plays a significant role in global carbon emissions. According to the World Economic Forum, logistics accounts for about 8% of global carbon emissions. Here’s a breakdown of the contributions from various logistics sectors:

| Logistics Sector | Approximate Contribution to Global CO₂ Emissions | Source |

|---|---|---|

| Road Freight (Trucks) | ~5.5–6% | McKinsey (2023), ISO.org (2023) |

| Air Freight | ~1.9% | Stand.earth (2024), MIT Climate Portal |

| Maritime Shipping | ~3% | International Council on Clean Transportation (ICCT, 2023) |

| Warehousing (Energy Use) | ~0.8% | DAACap.com (2023), ISO.org |

| Total (Logistics Overall) | ~8–11% | World Economic Forum, ISO.org, McKinsey |

These figures highlight the substantial environmental impact of traditional logistics practices.

Air freight, in particular, has seen a significant increase in emissions. A 2024 analysis by Stand.earth found that greenhouse gas emissions from air freight operators have increased by 25% since 2019, with the U.S. accounting for over 40% of global emissions.

Urban last-mile deliveries also contribute to rising emissions. A report by the World Economic Forum estimates that urban last-mile delivery emissions are on track to increase by over 30% by 2030 in the top 100 cities globally.

Warehousing, while often overlooked, contributes to greenhouse gas emissions primarily through energy usage for lighting, heating, cooling, and operating equipment such as forklifts. According to a study published in Transportation Research Procedia, warehousing operations generate both direct (Scope 1) and indirect (Scope 2 and 3) emissions, depending on their energy sources and supply chain integrations.

Key Benefits of Sustainable Logistics

1. Environmental Preservation

Transitioning to low-emission vehicles and optimising delivery routes are pivotal steps in reducing pollution and conserving fuel. By adopting cleaner transportation methods, companies can significantly decrease their carbon footprint, contributing to a healthier planet.

2. Cost Efficiency

Sustainable logistics is not only environmentally responsible but also economically advantageous. Implementing fuel-efficient technologies and redesigning packaging can lead to substantial cost savings. For instance, DHL’s GoGreen program has shown that integrating sustainable practices can enhance operational efficiency, leading to financial benefits.

3. Regulatory Compliance

Governments worldwide are enforcing stricter emissions standards to combat climate change. In the United States, the Environmental Protection Agency (EPA) announced new regulations in March 2024 aimed at reducing harmful air pollutant emissions from light-duty and medium-duty vehicles starting with model year 2027. Companies that proactively adopt sustainable logistics practices position themselves ahead of regulatory requirements, avoiding potential penalties and enhancing their reputation.

4. Brand Reputation and Customer Loyalty

Consumers are increasingly prioritising sustainability in their purchasing decisions. A Nielsen global survey revealed that 73% of respondents would definitely or probably change their consumption habits to reduce their environmental impact. By transparently showcasing sustainable logistics efforts, companies can differentiate themselves in the market, fostering customer loyalty and attracting environmentally conscious consumers.

5. Workforce Satisfaction

Implementing green practices within logistics operations can lead to improved workplace morale. Employees often take pride in working for organisations that prioritise environmental responsibility, leading to increased job satisfaction and retention.

Real-World Case Studies

1. CJ Darcl Logistics

CJ Darcl Logistics, a major player in India’s freight sector, is making bold moves toward sustainability. In 2024, the company transported heavy machinery—specifically excavators—by rail from Chennai to Ballabgarh, demonstrating a commitment to reducing road congestion and emissions. Additionally, CJ Darcl introduced electric vehicles for intra-city cargo movements in Bangalore, marking a significant step in embracing cleaner transportation options. Looking ahead, the company plans to integrate AI and IoT technologies to optimise routes and monitor emissions, aiming for a smarter, greener logistics network.

2. Crowley Maritime

Crowley Maritime, a U.S.-based logistics and marine solutions company, is redefining sustainability by blending electrification with renewable energy. In partnership with the Port of San Diego, they’ve launched eWolf—the nation’s first all-electric, zero-emission tugboat. Supporting this groundbreaking vessel is a shore-based microgrid powered by solar panels and battery storage, dramatically cutting reliance on fossil fuels. The system saves around 30,000 gallons of diesel annually and significantly reduces greenhouse gas emissions.

3. Amsterdam’s Waterway Logistics: Rethinking Urban Delivery

Amsterdam is reimagining urban logistics by shifting freight transport from congested roadways to its extensive canal network. A study highlights the potential benefits of this approach, including a 28% reduction in costs, a 43% decrease in vehicle weight, and an 80% cut in travel distances within the city centre. By integrating electric vehicles for last-mile delivery, the city aims to further enhance environmental sustainability. This innovative use of waterways exemplifies how cities can leverage existing infrastructure to create greener logistics solutions.

Key Components of Sustainable Logistics

1. Green Transportation

Transportation is a major contributor to carbon emissions, but companies are taking steps to change that. FedEx, for instance, has invested in electric delivery vans like the Chevrolet BrightDrop Zevo 600 to reduce emissions in last-mile deliveries. These electric vehicles are part of a broader shift toward cleaner transportation options, including hydrogen fuel cells and biodiesel. By adopting these technologies, logistics providers are not only cutting emissions but also reducing fuel costs and maintenance needs.

2. Smart Warehousing

Warehouses are becoming smarter and more sustainable. Amazon’s fulfilment centres in Europe have introduced Vulcan, a robot with touch-sensing capabilities that can identify items by feel, improving the efficiency of picking operations. These advancements, combined with energy-efficient lighting and heat-recovery systems, are helping to reduce the environmental impact of warehousing operations.

3. Eco-Friendly Packaging

Packaging plays a significant role in the environmental footprint of logistics. Companies like Footprint and Vegware are leading the way in developing compostable and biodegradable packaging materials. Footprint, for example, creates fibre-based alternatives to plastic packaging, while Vegware offers plant-based compostable foodservice disposables. By adopting such eco-friendly packaging solutions, businesses can significantly reduce waste and promote a circular economy.

4. Route Optimisation & AI

Artificial intelligence is transforming logistics by optimising delivery routes and reducing fuel consumption. Advanced algorithms can analyse traffic patterns, weather conditions, and delivery schedules to determine the most efficient routes. A study on AI models for sustainable logistics optimisation in the USA demonstrated that such technologies can enhance logistics efficiency, reduce carbon footprints, and contribute to a more resilient supply chain.

5. Reverse Logistics

Managing product returns efficiently is crucial for sustainability. Reverse logistics involves reusing products or materials, minimising waste, and recovering value from returned items. Efficient reverse logistics systems can reduce the environmental impact of returns and improve customer satisfaction. For example, companies that implement effective returns management strategies can optimise operational efficiency while addressing customer retention concerns.

Challenges and How to Overcome Them

1. High Initial Investment

Adopting eco-friendly logistics can feel like a hefty investment at first, whether it’s swapping out a fleet for electric vehicles or upgrading a warehouse to be more energy efficient. However, these upfront costs often pay off over time. Many companies that have taken advantage of environmental tax credits—especially those aimed at improving vehicle efficiency—have reported up to a 20% drop in maintenance expenses. Additionally, the U.S. Inflation Reduction Act offers a 30% Investment Tax Credit for qualifying renewable energy projects, further offsetting initial expenses.

2. Limited Infrastructure

The scarcity of EV charging stations and alternative fuel facilities can hinder the adoption of sustainable logistics. However, collaborative efforts are underway to expand this infrastructure. For example, Investopedia reported that seven major automakers, including General Motors and BMW, have partnered to install at least 30,000 EV chargers across the U.S. and Canada, aiming to alleviate “range anxiety” and support EV adoption.

3. Complex Supply Chains

Coordinating across diverse suppliers and regions adds complexity to sustainable logistics. Implementing technologies like blockchain can enhance transparency and traceability within supply chains. Blockchain’s decentralised ledger system ensures secure and immutable records of transactions, facilitating better coordination among stakeholders.

Actionable Advice for Businesses

1. Start with a Carbon Audit

Before you can improve, you need to measure. Conducting a carbon audit helps you understand where your logistics emissions are coming from—be it fuel usage, warehousing, or last-mile delivery. Frameworks like the Global Logistics Emissions Council (GLEC) provide standardised methods for calculating emissions across transport modes, making it easier to benchmark and track progress.

2. Set SMART Sustainability Goals

Vague targets like “go green” won’t cut it. Instead, set SMART goals—Specific, Measurable, Achievable, Relevant, and Time-bound. For example, aim to reduce fleet emissions by 15% within 12 months or switch 30% of your deliveries to electric vehicles by 2026. Clear goals keep teams focused and accountable.

3. Collaborate with Suppliers

Your sustainability efforts are only as strong as your supply chain. Engage your suppliers and logistics partners in your green initiatives. This could mean co-developing sustainability training, sharing emissions data, or aligning on eco-friendly packaging. Building these relationships fosters transparency and shared responsibility.

4. Embrace AI and Smart Tech

Technology can be a game-changer. AI-powered route optimisation, for instance, can reduce empty miles and fuel consumption. Companies like Uber Freight are using AI to match loads more efficiently, cutting down on unnecessary trips and emissions. Investing in such technologies not only boosts sustainability but also improves operational efficiency.

5. Educate and Empower Your Team

Provide training to help employees understand their role in achieving sustainability goals. Recognise and reward green initiatives, and create platforms for employees to share ideas and successes. An informed and engaged workforce can drive meaningful change.

Learn More: Sustainable Practices in Retail: A Comprehensive Guide

Conclusion: Looking Ahead – The Future of Logistics Is Green

By 2030, sustainable logistics will be the standard, not the exception. Consumers are increasingly prioritising eco-friendly choices, governments are tightening carbon regulations, and investors are favouring companies with strong environmental, social, and governance (ESG) practices. Technologies like hydrogen-powered trucks, blockchain for transparent supply chains, and drone deliveries are transitioning from concepts to practical solutions.

According to a report by GlobalNewswire, the green logistics market is projected to reach approximately $3.3 trillion by 2030, growing at a compound annual growth rate of 8.32%. This growth is driven by innovations such as electric vehicles, smart warehouses, and renewable energy integration. Companies like DHL are already implementing electric bikes and delivery vans, achieving carbon-free deliveries in about half of Germany’s districts.

However, challenges remain. Infrastructure gaps and high initial costs hinder the adoption of electric trucks. To overcome these barriers, businesses must invest in sustainable technologies, collaborate with partners, and align with evolving regulations.

Whether you’re a supply chain manager, a small business owner, or a consumer, you have a role in this transformation. Embracing green logistics isn’t just about reducing emissions; it’s about building a resilient, future-ready supply chain that meets the demands of tomorrow.