Used Tyres Recycled into Export-Grade Fuel: The Promise and the Circularity Question

Every year, the world retires millions of tyres. Some are repurposed into playground surfaces or crumb rubber for roads, but a big slice still ends up as energy: burned directly or processed into fuels. A growing industry now uses pyrolysis — heating shredded tyres without oxygen — to pull off three main products: a dark oily liquid often called tyre pyrolysis oil (TPO), a carbon-rich char (recovered carbon black, rCB), and steel wire. Proponents say TPO can be refined into export-grade industrial fuel or blended into transport fuels, turning a waste problem into revenue.

Critics ask whether exporting that fuel simply shifts pollution around, and whether the loop is truly circular when valuable carbon leaves the material economy as fuel rather than returning to long-lived products. According to Klean Industries, a developer of commercial tyre-to-fuel projects, pyrolysis can produce renewable transport fuels and recovered carbon black when done at scale with downstream refining.

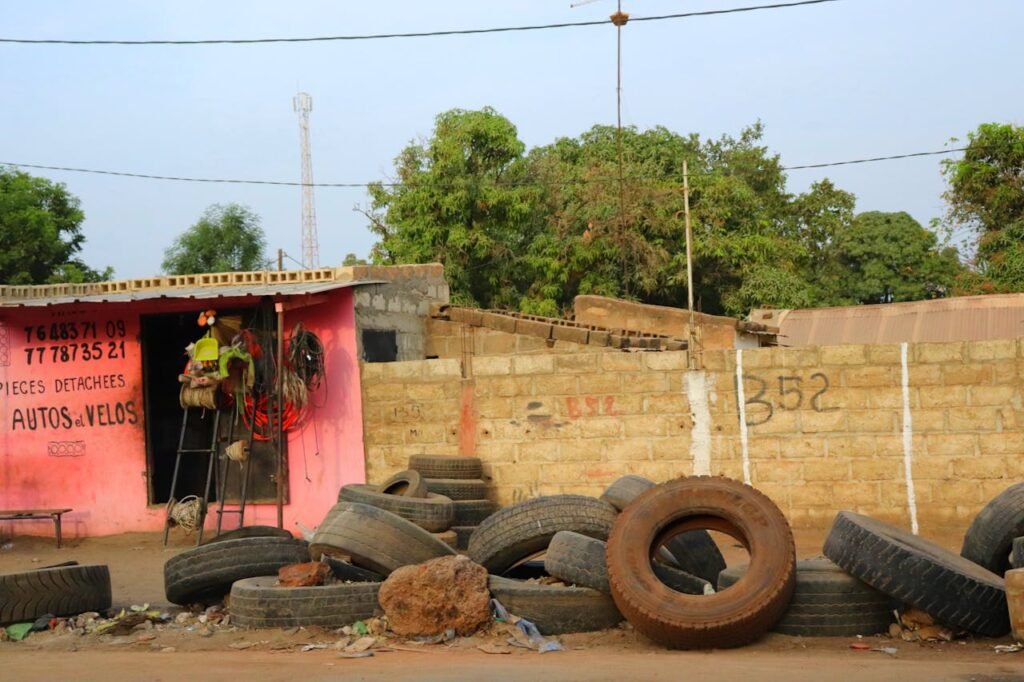

Real-World Projects and Human Stories

Across continents, small industrial plants and large projects have been set up to turn tyre waste into fuel. In the UK, a well-publicised project aims to convert end-of-life tyres into lower-carbon transport fuels and recovered carbon black; the company involved says the model is commercially proven and scalable. According to Klean Industries, their UK work looks to supply underserved low-carbon fuel markets while helping solve a tyre waste backlog.

Not all stories are rosy. In Oyo State, Nigeria, local regulators shut a tyre-to-fuel facility in early 2024 after monitoring visits found unhealthy emissions, contaminated surfaces from carbon black, and poor worker protections. The state’s environment commissioner said air quality near the plant exceeded national limits and described the workplace as unsafe, citing a lack of personal protective equipment and no potable water for workers. This closure is a concrete reminder: technology alone isn’t enough — operating standards, enforcement and worker safety matter. A report by the local regulator in 2024 found the plant’s practices contravened environmental regulations and posed health risks to staff and neighbours.

Elsewhere, smaller pyrolysis installations — sold by international plant suppliers — have been installed in parts of Africa and Asia to “add value” to tyre waste. These buyers typically point to income from selling pyrolysis oil and carbon char, and sometimes to energy independence or landfill avoidance. But plant vendors and early operators regularly warn that oil quality, emissions control, and markets for recovered carbon black are critical to commercial success. According to Beston Group and other suppliers, typical plant yields and operational design strongly affect whether the operation is profitable and compliant.

What the Science and Standards Say

Technically, yields from tyre pyrolysis are consistent enough to be useful: many sources report roughly 40–45% liquid oil, 30–35% char (carbon black), around 10–15% steel, and the rest as gas or process losses — although these numbers vary by tyre type and process design. According to Klean Industries’ process guide and several academic reviews, those figures are typical for commercial processes.

On environmental performance, the literature is mixed, but it is clear that outcomes depend heavily on how the plant is built and managed. Comparative life-cycle analyses (LCAs) that model full systems — from tyre collection through processing and end use of the products — show a wide range of results. Some LCAs find that pyrolysis, when paired with high-quality emissions controls and when TPO displaces heavier fossil fuels, can lower net greenhouse-gas intensity compared with incineration or landfill. Other LCAs note significant climate and local air-pollution burdens if plants use poor combustion controls or the oil replaces cleaner fuels. A comparative life-cycle assessment in recent years found that environmental impacts differ by end-use pathway and that pyrolysis can improve outcomes only under certain operating and market conditions.

Health and regulatory guidance also matter. International technical guidelines for sound management of waste tyres stress that thermochemical processing must meet strict environmental and health standards, including controls for particulate matter, volatile organics and persistent contaminants — and must ensure worker safety. The Basel/UN technical guidance frames pyrolysis as a technology with potential if implemented under environmentally sound management; without that oversight, hazards to communities and workers are likely. A UN technical guidance document in 2024 emphasised rigorous environmental controls for any tyre processing technology.

Market reality complicates the circularity claim. A 2023 industry summary from the U.S. Tire Manufacturers Association (USTMA) showed that tyre-derived fuel (TDF) remains the largest “reclaim” market for end-of-life tyres in some regions, used by utilities and pulp mills as a fossil-fuel substitute. Turning tyres into fuel that is burned — whether locally or after export — recovers energy but does not preserve the embodied carbon in long-lived materials like asphalt or products using recycled rubber. In other words, the loop closes on waste disposal but not on carbon retention. A report by USTMA in 2023 found that TDF accounted for a major share of ELT reuse markets.

Recent technical research has also explored blending and refining options. Laboratory and engine studies have tested TPO blended with hydrotreated vegetable oil (HVO) or conventional diesel, finding that some blends can work in engines and reduce reliance on fossil feedstocks if the pyrolysis oil is upgraded and blended properly. But the studies repeatedly caution that raw TPO requires refining and quality control before it becomes a reliable, export-grade fuel that meets fuel standards. According to recent experimental work, blends of TPO with HVO show promise but require careful treatment and emissions testing.

Where this Leaves Policy and Practice — Actionable Advice

The technology is neither an instant fix nor an automatic green win; whether tyre-to-fuel becomes a scalable, responsible solution depends on three practical things: design, standards, and markets. First, plants must be built to modern emissions standards with continuous monitoring and clear public reporting. Regulators in countries where plants are operating should adopt and enforce the international best practices set out by organisations like UNEP and relevant national environmental agencies. The UN technical guideline in 2024 argued for strict environmental controls and traceability across tyre management systems.

Second, the oil must be upgraded, certified and used in ways that reduce net carbon and pollution compared with alternatives. If a plant produces low-quality oil that is burned with minimal controls or exported into markets with lax combustion rules, the climate and health benefits disappear. Research shows that high performance and low emissions require downstream refining (to diesel-grade or marine fuel specifications) and robust testing to make TPO a true replacement for heavier fossil fuels. According to scientific evaluations, TPO can be part of a lower-carbon pathway only when upgraded and blended under controlled conditions.

Third, recovered carbon black must have a credible market. Many studies and industry reports note that rCB is only valuable if it can be upgraded to standards usable in tyres, rubber goods, or other durable products. If rCB is low quality and piled up as waste, the circular claims weaken. LCA work comparing pathways found that reusing carbon in long-lived products generally yields better circularity than using it for fuel.

Finally, governments and investors should demand transparency. Operators should publish monitoring data and independent audits; regulators should make permits conditional on community health protections and off-take contracts that ensure TPO is refined and used cleanly. The Oyo State closure shows what can go wrong when rules and oversight are weak: workers and neighbours bore the health burden, and the plant was shut down. A local government report from 2024 documented breaches of environmental standards that led to enforcement action.

Conclusion

Tyre-to-fuel technology can turn a stubborn waste stream into energy and useful co-products — but it is not automatically circular or clean. The difference between a plant that helps the climate and one that harms people is not the reactor design alone; it is the decisions that follow: who monitors emissions, who upgrades the oil, who buys the carbon black, and who enforces the rules.

If policymakers insist on best-practice design, independent monitoring, and guaranteed upgrading of pyrolysis oil before export, pyrolysis can be a responsible element of a broader circular strategy — but only when it complements reuse and long-lived material solutions rather than replaces them. International technical guidance and careful life-cycle studies provide the map; real success depends on governance and markets. According to UNEP technical guidance and multiple recent LCAs, this combination of technology, oversight and market development is essential for any tyre-to-fuel solution to be genuinely circular.